PROFORCE

Installation and Operating Manual

TABLE OF CONTENTS

TABLE OF

CONTENTS

INTRODUCTION

OVERVIEW

SECTION I

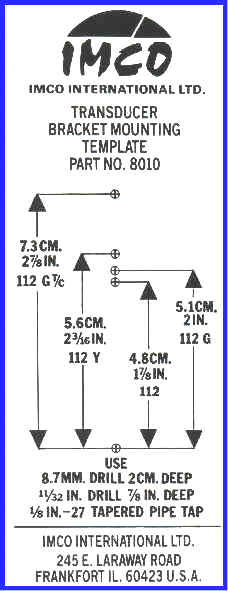

TRANSDUCER BRACKET DRAWING

Page 1—Transducer Bracket Template with Mounting Dimensions

Page 2—Piezo Transducer Drawing with Dimensions

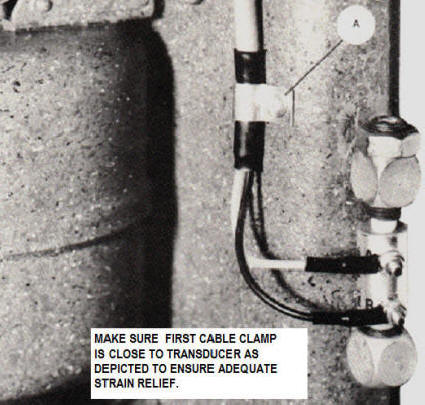

Page 3—Piezo Transducer with Cable Clamp on Press Frame

SECTION II

PIEZOELECTRIC TRANSDUCER INSTALLATION

Page 1—Piezo Transducer Mounting

Instructions

Page 2—Drawing for OBI, GAP, C-Frame & Press Brake

Page 3—Drawing Straight Side Press, Column Mounting 112G

Page 4—Drawing Straight Side Press, Pitman Mounting 112

Page 5—Drawing of Pitman Mounting Locations

SECTION III

TERMINAL BLOCK WIRING DESCRIPTIONS

Page 1—Terminal Block Points 1 - 4

POINT 1 - +24 Volt D.C.

POINT 2 - Grd. Input

POINT 3 - Grd. Output

POINT 4 - Analog Signature Output

Page 2—Terminal Block Points 5 - 9 TRANSDUCER INPUTS

Page 3—Piezoelectric Transducer Descriptions

Page 4—Terminal Block Points 10 - 12 CALIBRATING CAPACITORS

Page 5—Terminal Block Points 13 - 16

POINT 13 - Grd. (output to IMCO “Read Me” device)

POINT 14 - Peak Output

POINT 15 - +24 Volts (output to IMCO “Read Me” device)

POINT 16 - Cal (Calibrate)

Page 6—Terminal Block Points 17 - 19

POINT 17 - Trim Ref (Trim Reference)

POINT 18 - Peak Reset

POINT 19 - Display Reset

SECTION IV

CONNECTING PROFORCE I/O MODULE TO PLC

Page 1—Determining Cable Length, Minimizing

Electrical Noise Interference, Preparing The Cable

Page 2—Preparing The Cable, continued

Page 3—Wiring the Cable and Connecting to Proforce I/O Module,Minimizing Ground

Loops

SECTION V

BLANKING/FORMING SWITCH

Mode of Operation - Set Position of Switch To Blanking or Forming

INTRODUCTION

Our new, low cost small size

(100mm x 80mm x 25mm) Proforce Piezo I/O Module with Peak Indicating is D-Rail

mounted and work in conjunction with any manufactures PLC or Industrial PC. Proforce

Piezo I/O Module is used for one (1) channel of Load Monitoring. They can

work with any press tonnages or press speeds.

The Proforce Piezo I/O Module offers the ability to customize Load Monitoring

requirements by adapting customized software programs. They can program load

trip point for both Press and Dies. Hidden menus are easily created to monitor

press overload and die overloads for warranty purposes or other information that

may be required.

The Analog of the Proforce Piezo I/O Module feeds directly into the PLC or

Industrial PC, A to D Converter Board. The output signal is 0 - 10 Volts. - 24

Volt input.

All types of IMCO's Piezoelectric Transducers are used with the Proforce Piezo

I/O Module. Column mounted, Pitman mounted and "Satellite" In-Die Transducers

offer suitable mounting choices for the Proforce Piezo I/O Module.

FEATURES

OVERVIEW

PROFORCE

PIEZO ANALOG-DIGITAL I/0 MODULE

MODEL NO. PZO-30AP

SECTION I

TRANSDUCER BRACKET MOUNTING

Page 1

Stick-on

templates are supplied with all Proforce Piezo I/O Modules. Determine the

mounting bracket locations based on the type of piezoelectric transducers to be

used and the optimum output mounting location for piezoelectric transducers to

be used. . Attach template to the chosen location . Drill and tape the two

appropriate holes using the self-adhesive bracket mounting template (see

Template No. 8010 ) to determine correct hole spacing . Make sure

that in drilling the holes, the piezoelectric transducers will remain parallel

to the mounting surface (Example: column or pitman's). Use regular capacity 3/8

inch or 1/2 inch power drill; we suggest, if possible, a carbide tipped drill

bit, because the outer skin surface of the machine has a tendency to be tempered

hardened.

Stick-on

templates are supplied with all Proforce Piezo I/O Modules. Determine the

mounting bracket locations based on the type of piezoelectric transducers to be

used and the optimum output mounting location for piezoelectric transducers to

be used. . Attach template to the chosen location . Drill and tape the two

appropriate holes using the self-adhesive bracket mounting template (see

Template No. 8010 ) to determine correct hole spacing . Make sure

that in drilling the holes, the piezoelectric transducers will remain parallel

to the mounting surface (Example: column or pitman's). Use regular capacity 3/8

inch or 1/2 inch power drill; we suggest, if possible, a carbide tipped drill

bit, because the outer skin surface of the machine has a tendency to be tempered

hardened.

Use a 1/8 IN.— 27 Inch tapered (conical) pipe tape.

IMPORTANT: DO NOT SUBSITTUTE A NON TAPERED TAPE

After drilling and tapping the holes, apply a light oil or grease for lubrication and insert both top and bottom brackets; top brackets have the lock nuts and should be mounted on top. Jam brackets into frame with open end wrench so as to get square part of bracket body as close as possible to column or frame of Press . Do not remove the top bracket set screw when jamming into press frame. Make sure brackets are tight. Lock nuts should be “kissing” the frame or column.

NOTE:

Piezoelectric transducers are measuring micro strain in frame of Press. Brackets

should be tightened into Press frame as close as possible to assure maximum

piezoelectric transducer signal.

TORQUE TRANSDUCERS IN BRACKETS TO 15 INCH LBS.

SECTION I

TRANSDUCER BRACKET MOUNTING

Page 2

The IMCO Load Monitor and piezoelectric transducers are ruggedly built to withstand normal industrial environment conditions and require minimal maintenance. However, each system can benefit from careful use and maintenance. It is recommended that the following procedure be carried out at a minimum frequency of every three months.

TRANSDUCERS

Each piezoelectric transducer is factory

pre-wired and terminal connections sealed. A visual inspection of seal and

connections is all that is required. Torque piezoelectric transducers to 15

inch/lbs. at time of installation or before calibration. They should not come

loose even when located on a moving connection and subjected to heavy shock. You

can torque again to 15 inch/lbs., if any piezoelectric transducers screw becomes

loose and the original calibration is maintained. Check to see that top locknut

remains securely fastened. If loose, tighten with regular wrench. A small drop

of LockTite or similar fluid should avoid future loosening of locknut.

SECTION I

TRANSDUCER BRACKET MOUNTING

Page 3

TRANSDUCER CABLES

Check to see if cables are in good condition and covering remains pliable. Cracked or damaged cable can cause erratic or lack of signal from piezoelectric transducers. Activation of each piezoelectric transducer is easily checked on press by sharply squeezing top and bottom piezoelectric transducer bracket. Hold sections between thumb and forefinger simulating a quick pressure on the piezoelectric transducer as when the press member is dynamically loaded. Appropriate meter needle (digital display) should indicate a response.

SECTION II

PIEZOELECTRIC TRANSDUCER

Page 1

INSTALLATION

IMPORTANT

Please Read

![]() Do not run any other AC or DC lines with the Piezoelectric

Transducer

wires. Keep them separate.

Do not run any other AC or DC lines with the Piezoelectric

Transducer

wires. Keep them separate.

![]() Before serviceman arrives for Calibration be sure

Proforce is mounted, power connected,

Before serviceman arrives for Calibration be sure

Proforce is mounted, power connected,

piezoelectric transducers are

mounted and connected to the Proforce I/O Module.

![]() Software program should be written for Press PLC or

Industrial PC is the responsibility of the user.

Software program should be written for Press PLC or

Industrial PC is the responsibility of the user.

![]() Record Proforce I/O Module serial number for future

reference.

Record Proforce I/O Module serial number for future

reference.

PIEZOELECTRIC TRANSDUCER MOUNTING INSTRUCTIONS

The following instructions are provided in a basic sequence for simplicity in installing the Piezoelectric Transducers on your machine . Please select appropriate reference to your type of machine and read entire sequence before installing your Piezoelectric Transducers.

The IMCO piezoelectric transducers supplied from the factory for all IMCO systems are shipped pre-wired. The standard pre-wired cables are determined by the mounting location either on the columns or pitman's of the press. Standard cable lengths for column or pitman mountings are applicable to most all types presses. Do not cut cable until length from transducers to the mounted Proforce I/O Module is determined. If the cable lengths are not long enough, custom cable lengths can be requested.

Typical mounting locations are recommended to obtain maximum output from IMCO piezoelectric transducers. While there are possible alternates, it is suggested that you contact the factory before selecting one. We do not advise pitman mounting if your pitman is split or it has an adjustment mechanism in the pitman.

The IMCO piezoelectric transducers are measuring micro strain. Brackets should be tightened and jammed into the press frame or pitman's as close as possible to assure maximum transducer signal. Make sure the brackets remain parallel to the mounting surface (i.e. columns or pitman's). Use the supplied mounting template to determine spacing distance between top and bottom mounting brackets.

SECTION II

OBI - GAP - C-FRAME - PRESS

BRAKES

Page 2

Column Mounting

112G Piezoelectric Transducer

IMCO piezoelectric transducers are normally placed, one at the back of each frame (see Figure No. 1) for simplicity of mounting. Each IMCO piezoelectric transducer is located between mounting brackets positioned approximately on a center line between the top and bottom of the gap, excluding any bolster plates. This location permits individual readout of peak load on each frame.

If for any reason the IMCO piezoelectric transducers cannot be located at the back of each frame, they can be placed on the pitman. Two IMCO piezoelectric transducers per pitman mounting connected in parallel will provide only a single channel of readout.

Note:

SECTION II

STRAIGHT SIDE PRESS

Page 3

Column

Mounting

112G Piezoelectric Transducers

Location of IMCO piezoelectric transducers on straight side presses should be on the columns front and back, (not the sides) away from keyways. One IMCO piezoelectric transducer for each column should be mounted approximately on a center line between the top of the ram and the bottom of the bed, excluding any bolster plates, to assure continued optimum output and positive response. (see Figure No. 2 and Figure No. 3).

Note: Do not substitute or splice in an alternate type cable.

Use only Belden #1503A for Column Mounting

TOP VIEW - STRAIGHT SIDE PRESS

SECTION II

STRAIGHT SIDE PRESS

Page 4

Pitman Mounting

112 Piezoelectric Transducers

Note: Do

not substitute or splice in an alternate type cable.

Use only Belden #83319 for Pitman Mounting.

Attach two IMCO piezoelectric transducers on each pitman located 180 degrees from each other and as close to the directional axis of rotation as possible. Wiring will be in parallel. We do not advise pitman mounting if your pitman is split or it has an adjustment mechanism in the pitman. (see Figure No. 4, Figure No. 5, Figure No. 6 and Figure No. 7)

PITMAN VIEW

SECTION II

STRAIGHT SIDE PRESS

Page 5

Pitman Mounting

112 Piezoelectric Transducers

PITMAN VIEW

SECTION III

TERMINAL BLOCK POINTS

Page 1

SECTION III

TERMINAL BLOCK POINTS

Page 2

SECTION III

TRANSDUCER DESCRIPTIONS

Page 3

The Proforce Piezo I/O Module is capable of using any IMCO 112 Series Piezoelectric transducer and can be wired for tension or compression by switching the A + B points on the transducer input terminal block Points 5 through 9.

Transducer

Input

Terminal Block Points 5 - 9

![]()

112 IDS In-Die

Satellite Piezoelectric Transducer

112 Pitman Mounted

Piezoelectric Transducer

112 are used on the

connecting rods or pitman's of the press, because the stresses on the pitman's

are greater than on the columns. The lower output 112 transducer is suitable for

pitman mounting. Two (2) 112 transducers are pre-wired in parallel and mounted

on each pitman or connecting rod. One (1) 112 transducer is mounted on the front

of the pitman and the other is mounted on the back of the pitman, 180 degrees

apart in the direction of the rotation compensating for bending of the pitman.

Even though the 112 transducer is ideally suited for pitman mounting with its

lower output, it does not limit its mounting use in other areas. 112 transducers

are wired for compression with Teflon cable, which is impervious to oil and

maintains its flexibility. (wiring diagram “Terminal Block Points 5 through 9”,

separate sheet.)

112G Column Mounted

Piezoelectric Transducer

112G Column Mounted Transducer wired in parallel

(2nd Parallel Sensor)

SECTION III

TERMINAL BLOCK POINTS

Page 4

Calibrating Capacitors

SECTION III

TERMINAL BLOCK POINTS

Page 5

SECTION III

TERMINAL BLOCK POINTS

Page 6

SECTION IV

CONNECTING TO I/O MODULE TO PLC

Page 1

DETERMINING CABLE LENGTH

When you determine the length of cable

required to connect Proforce I/O Module, remember to include additional length

to route the drain wire and foil shield to earth ground. Route cable long enough

to avoid signal attenuation.

MINIMIZING ELECTRICAL NOISE

INTERFERENCE

High speed analog signals are particularly

vulnerable to electrical noise. Take precautions when routing signal cables. To

help reduce the effects of electrical noise on analog signals, we recommend that

you:

![]() Install the PLC AND Proforce

I/O Module in a NEMA rated enclosure.

Install the PLC AND Proforce

I/O Module in a NEMA rated enclosure.

![]() Make sure that the PLC and Proforce I/O

Module is properly grounded.

Make sure that the PLC and Proforce I/O

Module is properly grounded.

![]() Use Belden cable # 1503A, # 8451 or #8761

(or equivalent) for signal wiring.

Use Belden cable # 1503A, # 8451 or #8761

(or equivalent) for signal wiring.

![]() Ground the cable properly.

Ground the cable properly.

![]() Route signal cables away from other

wiring or in grounded conduit.

Route signal cables away from other

wiring or in grounded conduit.

![]() Group Proforce I/O Modules away from AC

or high-voltage DC modules.

Group Proforce I/O Modules away from AC

or high-voltage DC modules.

We recommend re-checking Proforce I/O modules

operation after installing new machinery or

other sources of electrical noise near the I/O Modules.

ATTENTION:

Before wiring a Proforce I/O Module, disconnect Power from

the I/O Module and from any Power other Power source to the Module.

PREPARING THE

CABLE

1. At

each end of the cable, strip about 3 inches ( 76.19 mm) of casing to expose the

wires.

2. At the ground end of the cable (Figure 1), twist the drain wire and the foil

shield

together and bend them away from the cable. Using a hot air blower, apply

shrink wrap

where wires leave the casing.

3. At the other end of the cable, cut off the drain wire and foil shield. Apply

shrink wrap to

the junction where wires leave casing.

4. Trim the signal wires to 2 inch (50.8 mm) lengths. Strip about 3/16 inch

(4.76 mm) of

insulation away to expose the copper strands for connections.

5. Decide where you will connect the cable to earth ground, and ground it. Refer

to

GROUNDING THE

CABLE.

6. Connect signal wire (black and white) to terminal block and to input or

output device.

(see separate sheets for Wiring Terminal Block Points 1 through 19).

SECTION IV

CONNECTING TO I/O MODULE

TO PLC

Page 2

Continued: Preparing

The Cable

Repeat steps 1— 6 for each channel.

For each unused input channel, follow your A to D Board Instruction Manual.

GROUNDING THE

CABLE

Signal cable such as Belden #1503A, #8451

and #8761 ( or equivalent) has two signal wires (black and white), one drain

wire and a Foil shield (Figure 2). The drain wire and foil shield must be

grounded at only one end of the cable, not at both ends.

IMPORTANT: Ground the cable shield at one end having a good earth ground connection, such as at an I/O chassis mounting bolt or nearest ground bus in the I/O enclosure. Make this connection as short as possible. Do not ground the cable at the input to the A to D Board.

SECTION IV

CONNECTING TO I/O MODULE

TO PLC

Page 3

WIRING THE CABLE

ATTENTION:

Before wiring the Proforce I/O Module, disconnect PLC

System power, I/O Rack power, and module power.

CONNECT TO PROFORCE I/O MODULE

Use appropriate terminal block

points, depending on the speed of A to D Board.

MINIMIZING GROUND LOOPS

To keep the ground-loop current of input

circuits to a minimum, we recommend that you:

![]() Use the same power supply to power both input channels of a Proforce I/O Module

Use the same power supply to power both input channels of a Proforce I/O Module

![]() Or Tie together the grounds of separate power supplies.

Or Tie together the grounds of separate power supplies.

SECTION V BLANKING/FORMING SWITCH