Operating The Die-Tracker

CHAPTER ONE

"Start Up"

FIVE STEPS TO START USING DIE-TRACKER PLUS

STEP ONE:

ACTIVATE POWER

Once the Die-Tracker plus is installed and correctly calibrated, activate power to the Die-Tracker. Copyright IMCO International Ltd. will first appear on the Alpha/Numeric Display along with the current software version i.e.: 3.60.

After the copyright message, the Die-Tracker will switch to the last page from the factory set up on new systems. After you have set the initial operating limits the Die-Tracker will always switch to the last readings of the last page used in production.

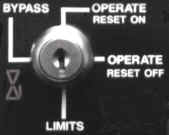

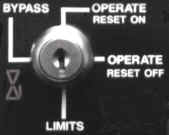

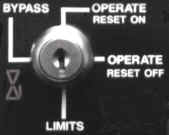

KEY LOCK SELECTOR SWITCH

STEP TWO : SETTING LIMITS

~Default limits have been

set at IMCO. You may use these limits or enter your own limits. If

you choose default limits proceed to step 3~

The "Limits" position is used to enter the limit values or change limit values

and to set the amount of parts to be counted on the Pre-Set Parts Counter.

Turn the Key Lock Selector Switch to the "Limits" position. There are

three limit values and the Pre-Set Parts Counter amount that needs to be

entered: 1) Press Limit; 2) Hi/Low Limits; 3)

Tracking Limits; 4) Pre-Set Parts Counter. The

first "Limit" will appear on the Alpha/Numeric Display, move

the arrow buttons

to increase or decrease the limit values or select the Die-Trackers

pre-programmed limits. Use the

star button to move to the next limit.

Always press the enter button

after a new value has been selected. Pre-Set Parts Counter digits are

moved left to right by pressing the star

button. The limit digit values are changed

by using the arrow button.

Press the enter button

after entering the new numbers of parts to be counted not after each entered

digit.

STEP THREE : BY PASS - SET UP

The "By-Pass" position is used when setting up dies. Turn the Key Lock Selector Switch to the "By-Pass" position. Set up the die in the press that is to be used for production. Make a good part. ~Press limits are always on even in the By-Pass position.~

STEP FOUR : BY PASS - RUN THE PRESS

The adaptive learning "Operate" has two selector switch positions. Operate "reset on" allows the operator to reset overloads/underloads or Operate "reset off" does not allow the operator to reset overloads. underloads. Turn the Key Lock Selector Switch to operate "reset off" or operate "rest on". After the Adaptive Learning Feature samples a part within 8 or 16 strokes, the Die-Tracker plus will calculate and set limits. ~Each time the system is powered up it will keep in memory the last readings.~ Change die after die and never manually set limits again.

STEP FIVE : RELEARN - RECALCULATE LIMITS SET POINTS

1) Press Reset Button - system will relearn or 2) Turn Selector Switch to By-Pass then immediately to any position. System will relearn.

"Limits"

Select the "LIMITS" position on the Key Lock Selector Switch

THE FIRST LIMIT DISPLAY WILL APPEAR:

AUTO HI +08 % (EXAMPLE)

Use arrows to Increase or Decrease Limit Values

![]()

![]() NEXT

LIMIT WILL APPEAR

NEXT

LIMIT WILL APPEAR

PRT LIMIT - 12345678 (EXAMPLE)

Press Star to move each Part Digit from left to right

![]()

![]() NEXT

LIMIT WILL APPEAR

NEXT

LIMIT WILL APPEAR

PRESS LIMIT 107% (EXAMPLE)

Use Arrows to Increase or Decrease Limit Values

![]()

Continue following procedure until all limits

have been entered or changed using the Arrow

Buttons to Increase or Decrease the limits

value, Star Button to move to the next limit

or move digits of the parts count (PRT LIMIT) and Enter

Button to enter or change all limit values.

Refer to Chapter Two for

description of each limit.

CHAPTER TWO

"Understanding The Key Lock Selector Switch"

KEY LOCK SELECTOR SWITCH

The Key Lock Selector Switch has Four Functions

Positions that may be used to operate the Die-Tracker Plus. The Key Lock

Selector Switch can be turned to By-Pass then immediately to any operate

position allowing the Die-Tracker Plus to relearn.

~PRESS LIMITS ARE ALWAYS ON~

TURN KEY LOCK SELECTOR SWITCH TO SELECTED

POSITION

TURN KEY LOCK SELECTOR SWITCH TO SELECTED

POSITION

The Four Positions Available for Selection:

BY-PASS - OPERATE (RESET ON) - OPERATE (RESET OFF) - LIMITS

DESCRIPTION:

BY-PASS

This position is used for die

set-up or changing material. It allows the operator to bypass the Die

Limits which have been previously set and disables the Adaptive Learning program

from operating. ~The press

limits are always on even in the By-Pass position~

Relearn

The system will relearn by turning the Key Lock

Selector Switch to BY-PASS then immediately to any operate position.

OPERATE (RESET ON) Adaptive Learning

This position is used to engage the Die-Tracker Plus to operate. This position will allow the overloads, underloads, to be reset. The Adaptive Learning program will take an initial sampling of parts being made within 8 or 16 strokes (other stroke values are available upon request). It will then set the Hi/Low Limits and Tracking Limits with no further assistance from operator or programmer.

OPERATE (RESET OFF) Adaptive Learning

This position is used to engage the Die-Tracker Plus to operate. This position will not allow

the overloads, underloads to be reset. The Adaptive Learning program will take an initial sampling of parts being made within 8 or 16 strokes (other stroke values available upon request). It will then set the Hi/Low Limits with no further assistance from the operator or programmer.LIMITS

Press Limits - Press Capacity Overload Limit. ~Press Limits are always on and cannot be

~Press Limits are always on and cannot be By Passed.~Hi/Low Limits - These limits can be set and left for all dies regardless of their tonnage or can be specifically set for each die. This allows the user to select the percentage above or below the tonnage for a particular job at which the high or low limit will be actuated and allowing for variations in material hardness or thickness in any one coil.

Tracking Limits - The allowable hit to hit repeatable variation in tonnage. If the load changes more than the tracking limits, in a single stroke, the system signals the press to stop. Tracking Limits overlook the gradual changes in load and allow tight tolerances of plus and minus one percent (1%) to be set from one stroke to the next. Missfeeds, broken punches, part ejection failures and material run out can be detected. It is not affected by temperature changes in stock variation. Tracking Limits assure the repeatability of quality parts.

Pre-Set Parts Counter - Counts stroke in which enough tonnage is exerted to make a part. Can be pre-set to automatically stop press after a predetermined amount of parts have been made. When Pre-Set Parts Counter limits have been reached, the Alpha/Numeric Display will show count done.

NOTE: Use arrow buttons, star button and enter button for entering or changing the limits and Pre-Set Parts Counter.

Chapter Three

"Normal Operating Capabilities"

SIX PAGE SELECTIONS

"MAIN DISPLAY" 16 DIGIT ALPHA/NUMERIC DISPLAY

Die-Tracker Plus has six page selections in which the Die-Tracker normally functions:

Tons - Total Percent - Reverse Load - Strokes Per Minute (SPM) - Parts Count- Tracking Limits

While the press is running or not running, the operator can view the load of the press or dies by pushing the arrow buttons up or down. When a overload and/or underload is detected in the die or press, the cause of the condition will readout on the Main Display in exact words and will keep repeating itself until reset. The overloads and underloads can also be viewed on the Load Progression Bar Graphs ( see Chapter Four).

SELECTION OF PAGES AND DESCRIPTION:

PAGES 1 THROUGH 5 SHOWS THE STATUS OF THE SET LIMITS

TOTAL TONS

Total left side and right side readings in tons.

TOTAL PERCENTAverage of the left side percent readings and the right side percent readings displayed in percent.

REVERSE LOAD

Reads the reverse load of the press in percent when performing stripping operations or blanking jobs with snap through loads.

STROKES PER MINUTE

Speed of the press.

PRE-SET PARTS COUNTERCounts strokes in which enough tonnage is exerted to make a part. Can be pre-set to automatically stop the press after a pre-determined amount of parts have been made.

PAGE SIX SHOWS THE HIT TO HIT REPEATABILITY OF THE SET LIMITS

TRACKING LIMITS

The allowable

hit to hit repeatable variation in tonnage. If the load changes more than

the tracking limits, in any single stroke, the system signals the press to stop.

Tracking Limits overlook gradual changes in load and allow tight tolerances of

plus and minus one percent (1%) to be set from one stroke to the next.

Miss feeds, broken punches, part ejection failure and material run out can be

detected. It is not affected by temperature changes or stock variation.

Tracking Limits assure the repeatability of quality parts.

CHAPTER FOUR

"Tonnage Trend - Hi/Low Limits"

LOAD PROGRESSION BAR GRAPHS

Displays a quick visual reference of the tonnage trend in relation to the Hi and Low Limits that have been set. It shows how close the Die-Load is approaching the learned limits. Ten Led "Load Progression" Segments on the Bar Graphs offer a greater resolution for tonnage interpretation. Each segment between good and bad represents a specific change in load. When press is performing parts at the optimum working condition, the green lights are lit in the center of the bar graphs, any variation will gradually change the color from green to yellow, which can be acceptable to red which would not be acceptable.

HI/LOW LIMITS

Can be set and left for all dies regardless of tonnage or can be specifically set for each die. This allows the operator to select the percentage above or below the tonnage for a particular job at which the Hi or Low Limit will be actuated, allowing for variations in material hardness or thickness in any one coil of material.

CHAPTER FIVE

"Viewing Load Readings"

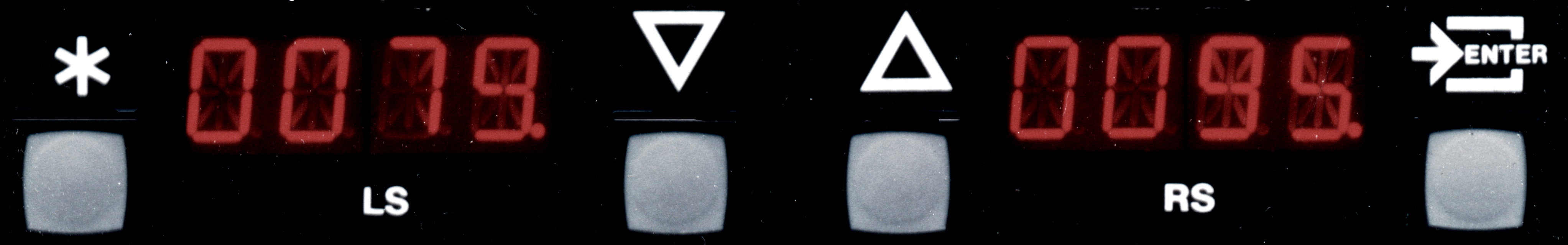

LOAD READINGS ON FOUR DIGIT DISPLAY

LEFT SIDE AND RIGHT SIDE FOUR DIGIT DISPLAYS

TOTAL TONS

The die load displayed on the Left and Right Side Displays in direct tons. The Total Tonnage of the die load is displayed on the Alpha/Numeric Display.

STROKES PER MINUTE

The die load displayed on the Left and Right Side Displays in direct tons. SPM is displayed on the Alpha/Numeric Display.

PARTS COUNT

The die load displayed on the Left and Right Side Display in direct tons. The Parts Count is displayed on the Alpha/Numeric Display.

REVERSE LOAD

The reverse load displayed on the Left and Right Side Display in percentage of load.

TOTAL PERCENT

The die load is displayed on the Left and Right Side Display in percentage of load. The total percent of the die load is displayed on the Alpha/Numeric Displays.

TRACKING LIMITS

The die load is displayed on the Left and Right Side display in percentage of load.

CHAPTER SIX

"Buttons"

USING BUTTONS TO OPERATE DIE-TRACKER PLUS

The buttons located on the "face Plate" provide

and easy,

practical approach when using the Die-Tracker Plus:

RESET BUTTON - ENTER BUTTON - ARROW BUTTONS - STAR BUTTON

Begin to understand each buttons operating function and the user will quickly bring about the Load Monitoring result they may require.

RESET BUTTON

The main system

RESET BUTTON is used to reset Overloads, Underloads or the Pre-Set Parts Counter values that have been reached.Note: The Key Lock Selector Switch can be turned to the operate position which will allow or not allow the overloads, underloads to be reset. Example: Operate (Reset On) Operate (Reset Off)

ENTER BUTTON

The

ENTER BUTTON must be used when changing Limit values or the Pre-Set Parts Counter values. When entering new Limit values or Pre-Set Parts Counter values, the ENTER BUTTON must be pressed or the new limit or pre-Set Parts Count values will not be accepted.ARROW BUTTONS

A.

The ARROW BUTTONS

are used to select a Page from the SIX PAGE SELECTIONS, Chapter Three, which

shows the status of the limits or hit to hit repeatability. The Page

selected appears on the Alpha/Numeric Display. Pages can be moved forward

or reverse using the ARROW

BUTTONS while

the press is running to review all the load monitoring information which is

occurring.

B.

When the Key Lock Selector Switch is in the Limits position the

ARROW BUTTONS will

increase or decrease the Limit values. Press

ENTER BUTTON when

changing Limit values or the new Limit value information will not be accepted.

Press the STAR BUTTON

(see below) to move to the next

Limit.

STAR

The

STAR BUTTON is used to move to the next Limit selection when the Key Lock Selector Switch has been turned to the Limits position.Press the

STAR BUTTON to move the digits on the Pre-Set Parts Counter from left to right. The digit parts count values are changed by using the ARROW BUTTONS. Press the ENTER BUTTON after the new total number of parts to be counted, not after changing each digit parts count value.PRESS IS NOT RUNNING

1. LOOKING AT THE LIMITS

Press the

STAR BUTTON from any of the SIX PAGE SELECTION to enter the LIMITS. Use ARROW BUTTONS to scroll forward or reverse to review the Limits that have been set. Limits may reviewed, but not changed. The Die-Tracker Plus will time out after 5 seconds and return to the last page selection or return to the last page selection when the press starts up.NOTE:

DIE NUMBER, PART NUMBER, STROKE PER PART AND QC COUNT (QUALITY CONTROL COUNT)

PRESS IS RUNNING

2. LIMITS INFORMATION - IT IS NECESSARY TO BE ON THE PARTS COUNT PAGE

Press the

ARROW BUTTONS to select Page Five PARTS COUNT. The Alpha/Numeric Display will change each time the STAR BUTTON is pressed to show Limit information. This information can be reviewed but not changed. The Die-Tracker Plus will time out after 5 seconds and return to the last page selection.NOTE:

DIE NUMBER, PART NUMBER, STROKE PER PART AND QC COUNT (QUALITY CONTROL COUNT)

CHAPTER SEVEN

"Specifications"

SPECIFICATIONS

EQUIPMENT

SYSTEM ENCLOSURE

13 3/4" ( 349.25 MM ) WIDE

5 3/4" ( 146.049 MM ) HIGH

11 1/2"( 292.099 MM ) DEEP

NEMA 12 SHOCK MOUNTED

POWER

115/220 VOLTS AC

50-60 HZ

RELAY CONTACT RATING

10 AMPS @120 OR 240 VOLTS

SPEED

5 STROKES TO 2500 STROKES PER MINUTE

DISPLAYS

MAIN DISPLAY: 16 DIGIT ALPHA/NUMERIC READOUT .54 HIGH CHARACTERS

TREND BAR GRAPHS: TWO BAR GRAPHS EACH WITH TEN LED LOAD PROGRESSION SEGMENTS

DIGITAL DISPLAYS: TWO DISPLAYS WITH .54 HIGH CHARACTERS