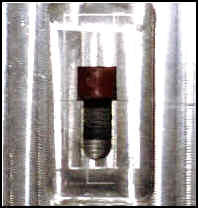

ABSOLUTE PART

MONITORING

SATELLITE

"IN-DIE" MONITORING

.470

Inch Round .310 Inch High

12 MM

8 MM

Piezoelectric In Die Parts

Monitoring creates the ability to produce and maintain high quality production

parts, by mounting in the dies Satellite transducers. Ideal for

progressive dies, transfer tooling and multi-station forming operations.

KISS Kit

Installation

KISS Kit

Installation

Easy

to install using our unique In Die KISS Kit

supplied with each Satellite

consisting of a 3/8”- 24 X 3/8” long Flat Point Set Screw (M10 X10

MM) and a 3/8”- 24 X 3/16” long Locking Ring (M10 X 5 MM) equipped with a milled

mounting hole for a precise transducer fit and designed to accommodate a torque

wrench to pre-stress the 112 IDS to 15 inch lbs. which accurately sets it after

installation.

A Piezoelectric transducer creates its own natural self-generating signal which

is 50,000 times greater than a strain gauge transducer signal. 100% of the load

signal is valid “load” signal not influenced by electrical “spiking”

noise disturbances which could be seen if using strain gauge type transducers

due to the necessity to amplify their signal. What you see is what you get! The

signal level coming from the Satellite

In Die transducer is showing you exactly what is occurring in the

dies. This pure signal level allows the In Die Satellite Transducer to monitor and

detect minute changes in the forming process that effect the quality of the

parts being produced. This technological edge gives the piezoelectric

Satellite In

Die transducer the natural advantage to perform superior Absolute Part

Monitoring by identifying a part that has not met the predetermined quality

standards or to maintain quality parameters needed to produce a repeatable,

acceptable part.

|

112 IDS Sensor |

"Kiss Kit" Set Screw |

Easily Milled 112IDS |

(Click Photo to

Enlarge and Print)

The

112 IDS IMCO In-Die Satellite

Piezoelectric transducers are mounted in the hardened die plate under a section

of die that has a critical load to be monitored. Multiple 112 IDS transducers

may be connected in parallel to increase signal strength and average the load

from a wider area in the die. 112 IDS transducers are wired for compression with

Teflon cable, which is impervious to oil and maintains its flexibility. Due to

its small size the 112 IDS does not compromise the integrity of the die plate in

which it is mounted.

The

112 IDS IMCO In-Die Satellite

Piezoelectric transducers are mounted in the hardened die plate under a section

of die that has a critical load to be monitored. Multiple 112 IDS transducers

may be connected in parallel to increase signal strength and average the load

from a wider area in the die. 112 IDS transducers are wired for compression with

Teflon cable, which is impervious to oil and maintains its flexibility. Due to

its small size the 112 IDS does not compromise the integrity of the die plate in

which it is mounted.

The 112 IDS Transducers can be used with any type of

IMCO Load Monitoring Systems.

Proforce

is ideally suited to be used with 112 IDS transducers.

Each

Proforce I/O Module

can be used with the 112 IDS to monitor one die station.

You can add an unlimited number of

Proforce

depending on your requirements for monitoring.

Proforce

I/O Module is

ideally suited to be used with 112 IDS transducers. Each

Proforce I/O Module

can be used with the 112 IDS to monitor one die station. You can add an

unlimited number of Proforce

depending on your requirements for

monitoring.

Click

on PROFORCE I/O/ MODULE

to find out more!

Click

on PROFORCE I/O/ MODULE

to find out more!